Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

DIP plug-in as an important part of the PCBA process, the quality of DIP plug-in determines the quality of PCBA processing, so we have some considerations when performing DIP plug-in.

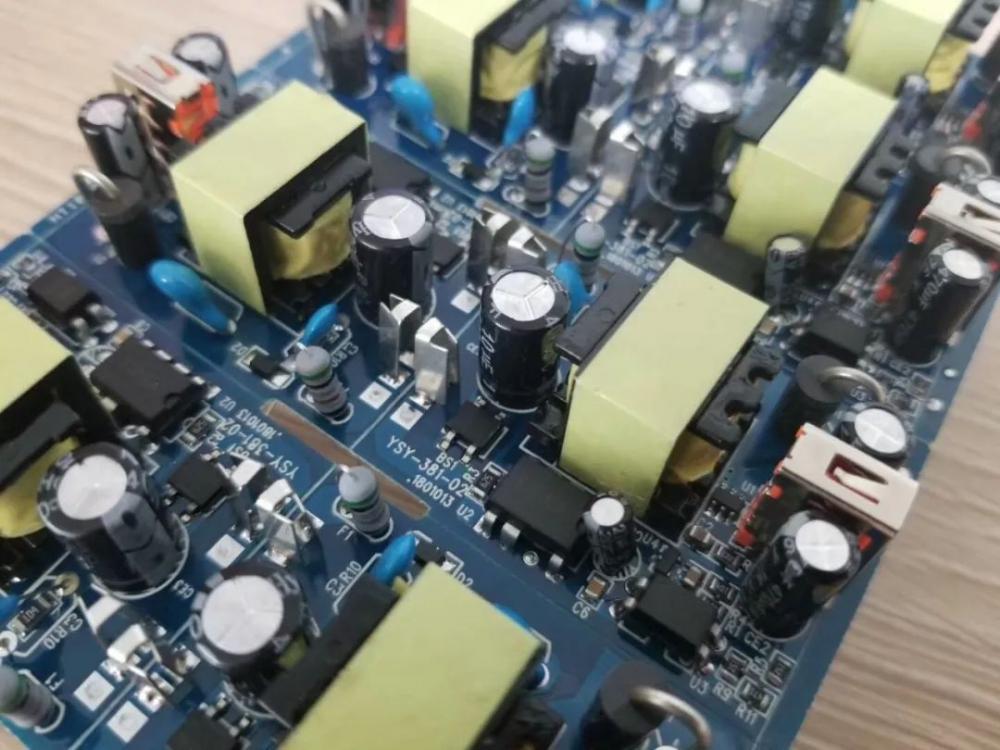

DIP plug-in process is after SMT placement process and is a part of PCBA process. DIP plug-in refers to the large size components that cannot be mounted by machine, but need to be manually plugged in, and then soldered by wave soldering afterwards, and the final product is formed.

DIP plug-in process can be roughly divided into plug-in, wave soldering, foot cutting, inspection, testing and other processes, plug-in is the chip processing components into the corresponding position of the PCB board, in preparation for the wave soldering; wave soldering is the plug-in good PCB board into the wave soldering conveyor belt, after spray flux, executive heat, wave repair welding, cooling and other links to complete the welding of the PCB board; foot cutting is to complete the welding PCBA board for cutting feet to achieve the right size; test after the completion of welding need to test the finished PCBA board, if the function is checked for defects, to repair and re-test processing, if the test is not a problem, packaging into storage.

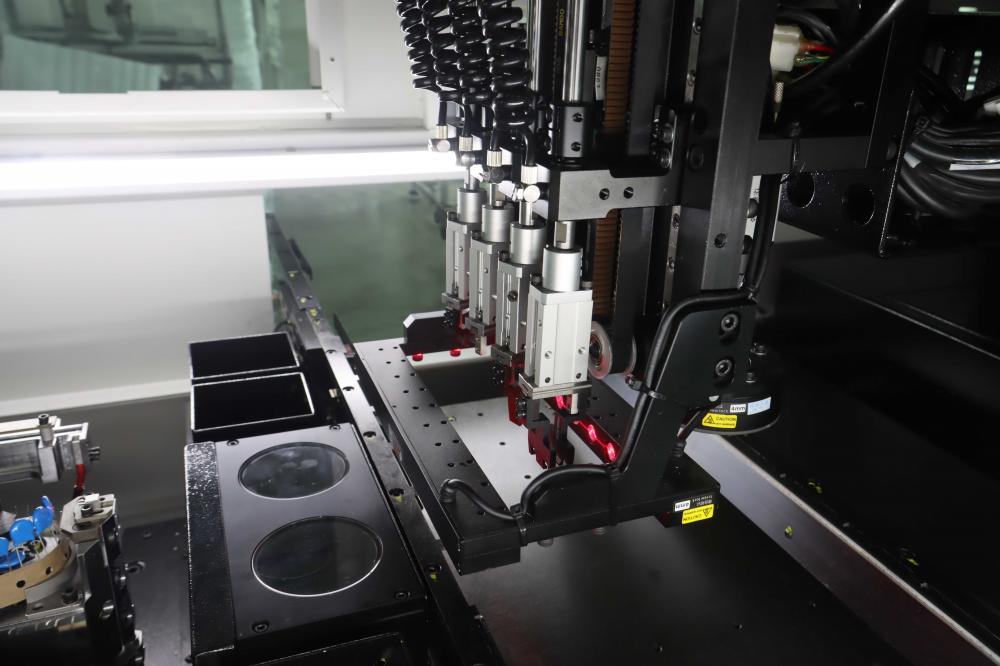

At present, some of the vertical and horizontal can already be standardized, but there are also shaped components due to different functions and manufacturers packaging and shape is different, so there are still many problems need to be overcome. Next, Xiao Xun will take you to understand the DIP plug-in process and what are the considerations! DIP plug-in as an important link in the PCBA process, the quality of DIP plug-in determines the quality of PCBA processing, so we need to pay attention to the following matters when carrying out DIP plug-in. 1.Before plugging in, the surface of electronic components need to be checked for unclean objects such as oil and paint. 2.In the plug-in process, must protect the electronic components and PCB flat paste, after the completion of the plug-in need to protect the electronic components is flush state, do not be uneven, and at the same time reported to protect the plug-in after the solder pins can not cover the pad. 4.When inserting the plug-in, you need to pay attention to the force of the plug-in, do not put too much force in the plug-in, resulting in component damage or PCB board damage. 5.When inserting electronic components do not insert the edge of the PCB board, pay special attention to the height of the electronic components and the spacing between the electronic components. Most of the current market DIP plug-in production line using semi-automatic + manual collaboration mode (i.e., automatic plug-in machine + manual plug-in) because of the long investment and return cycle (incoming packaging change to plug-in machine supply material standardization costs + equipment costs, etc.) popularization also needs time and market technology precipitation, in recent years, intelligent manufacturing plug-in machine technology has also made a great breakthrough, domestic and foreign electronic production equipment manufacturers have also launched the corresponding plug-in machine technology, in the next 10 years DIP plug-in will appear related to electronic components packaging standards shape standards, etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.