Electronic factory DIP plug-in soldering false solder and false solder bad detection - {AOI inspection equipment}

2022-01-03

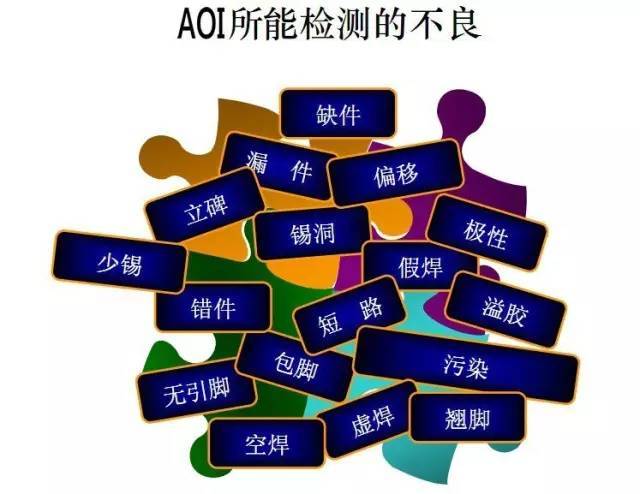

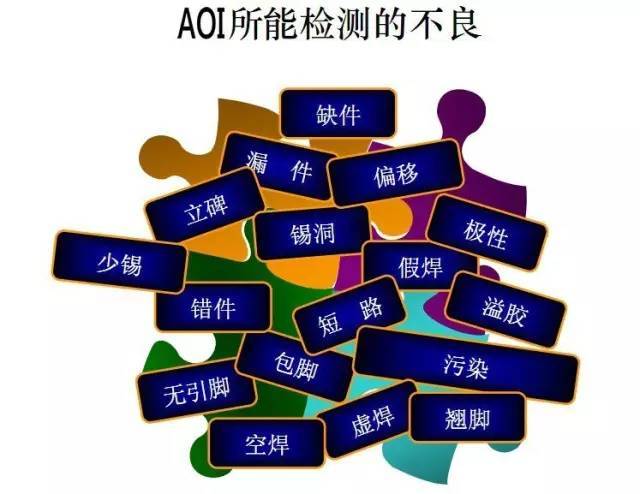

DIP is to insert components by hand, such as some large connectors, the equipment is not prepared to hit the PCB board, through the human or other automated equipment inserted into the PCB board. DIP line is mainly cast board clerk, demolition board clerk, plug-in clerk, furnace worker, visual inspection of the solder joint after the furnace. AOI can be placed in different positions after printing, before soldering, after soldering and before or after wave soldering DIP furnace. 1.AOI placed after printing - can detect the printing quality of solder paste for the process. It can detect the amount of solder paste is too much or too little, the position of the solder paste pattern is not shifted, and there is no adhesion between the solder paste patterns. 2.AOl placed after the mounting machine, before soldering - can be placed on the quality of the process inspection. Can detect component paste wrong, component shift, component paste reverse (such as resistor flip), component side stand, component loss, polarity error, as well as the patch pressure is too large caused by the adhesion between the solder paste graphics. 3.AOl placed in the reflow and wave soldering oven after - can be used for soldering quality inspection. Can detect component paste wrong, component shift, component paste reverse (such as resistor flip), component loss, polarity error, solder joint wetting humidity, too much solder, too little solder, leakage, false solder, bridging, solder ball (solder ball between pins), component warpage (vertical monument) and other welding defects.  AOI inspection of the circuit board covered by the bad is divided into two categories, one is called the component class bad, wrong parts, missing parts, reverse, offset, multiple pieces, broken, etc.. The other category is called solder joint class defects, namely, standing monument, tin ball, open solder, short circuit, less tin, and false solder. The shape of the body of the electronic components is regular, the image processing, the search of the body of the components, as well as the extraction of chromaticity and brightness is simple, so those who have used AOI know that the detection of component-type defects is relatively easy, the real difficulty of detection of AOI is the solder joint type of defects, especially the inspection of false solder. From the SMT process point of view, AOI can detect. Multi-part. Wrong parts. Offset. Reverse polarity. Low tin. Empty solder. Short circuit. Side stand and other process defects, AOI can only do cosmetic inspection, can not measure the hidden solder joints such as BGA, CSP, FlipChip and other invisible solder joint detection, AOI also does not have the ability to judge the circuit logic, so it can not completely replace ICT. RAY is a better way to inspect BGAs. That is another topic. According to the installation position, AOI can be divided into post-printing AOI, pre-furnace AOI, post-furnace AOI, and general-purpose AOI; post-printing AOI is installed after the solder paste printing machine and is mainly used to inspect the quality of solder paste printing. According to the difference of inspection function, post-printing AOI can be subdivided into 2D AOI and 3D AOI. 2D AOI can inspect the area of solder paste, while 3D AOI can also detect the volume of solder paste, of which 3D AOI is also specifically named 3D-SPI Solder Paste Inspection (Solder Paste Inspection) refers to the solder paste inspection system is a fully automatic non- Contact measurement, used after the solder paste printing machine, before the placement machine. The main function is used to detect the quality of solder paste printing, including volume, area, height, XY offset, shape, bridging, etc.; pre-furnace AOI is installed after the chip mounter or after the general-purpose mounter, mainly for detecting the condition of component placement; post-furnace AOI is installed after the reflow oven or after the wave soldering oven, mainly for detecting the condition of the component placement, as well as solder; as the name implies, the universal type AOI can be flexibly applied to the above AOI can be flexibly applied to each of the above processes and stations, and can complete all the above inspection functions.

AOI inspection of the circuit board covered by the bad is divided into two categories, one is called the component class bad, wrong parts, missing parts, reverse, offset, multiple pieces, broken, etc.. The other category is called solder joint class defects, namely, standing monument, tin ball, open solder, short circuit, less tin, and false solder. The shape of the body of the electronic components is regular, the image processing, the search of the body of the components, as well as the extraction of chromaticity and brightness is simple, so those who have used AOI know that the detection of component-type defects is relatively easy, the real difficulty of detection of AOI is the solder joint type of defects, especially the inspection of false solder. From the SMT process point of view, AOI can detect. Multi-part. Wrong parts. Offset. Reverse polarity. Low tin. Empty solder. Short circuit. Side stand and other process defects, AOI can only do cosmetic inspection, can not measure the hidden solder joints such as BGA, CSP, FlipChip and other invisible solder joint detection, AOI also does not have the ability to judge the circuit logic, so it can not completely replace ICT. RAY is a better way to inspect BGAs. That is another topic. According to the installation position, AOI can be divided into post-printing AOI, pre-furnace AOI, post-furnace AOI, and general-purpose AOI; post-printing AOI is installed after the solder paste printing machine and is mainly used to inspect the quality of solder paste printing. According to the difference of inspection function, post-printing AOI can be subdivided into 2D AOI and 3D AOI. 2D AOI can inspect the area of solder paste, while 3D AOI can also detect the volume of solder paste, of which 3D AOI is also specifically named 3D-SPI Solder Paste Inspection (Solder Paste Inspection) refers to the solder paste inspection system is a fully automatic non- Contact measurement, used after the solder paste printing machine, before the placement machine. The main function is used to detect the quality of solder paste printing, including volume, area, height, XY offset, shape, bridging, etc.; pre-furnace AOI is installed after the chip mounter or after the general-purpose mounter, mainly for detecting the condition of component placement; post-furnace AOI is installed after the reflow oven or after the wave soldering oven, mainly for detecting the condition of the component placement, as well as solder; as the name implies, the universal type AOI can be flexibly applied to the above AOI can be flexibly applied to each of the above processes and stations, and can complete all the above inspection functions.  AOI can be divided into online AOI and offline AOI according to the way it is used; online AOI is installed in the production line and can be synchronized in real time. Offline AOI, on the other hand, does not need to be installed in the production line, and can flexibly inspect circuit boards on multiple production lines. Offline AOI includes in-line AOI for off-line use, and desktop AOI. The machine replaces manual visual inspection, reducing human involvement and improving product quality and consistency.

AOI can be divided into online AOI and offline AOI according to the way it is used; online AOI is installed in the production line and can be synchronized in real time. Offline AOI, on the other hand, does not need to be installed in the production line, and can flexibly inspect circuit boards on multiple production lines. Offline AOI includes in-line AOI for off-line use, and desktop AOI. The machine replaces manual visual inspection, reducing human involvement and improving product quality and consistency.