Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

What are the classifications of foot Cutting Machine? How to use the foot cutting machine? What are the functions of the vibration plate?

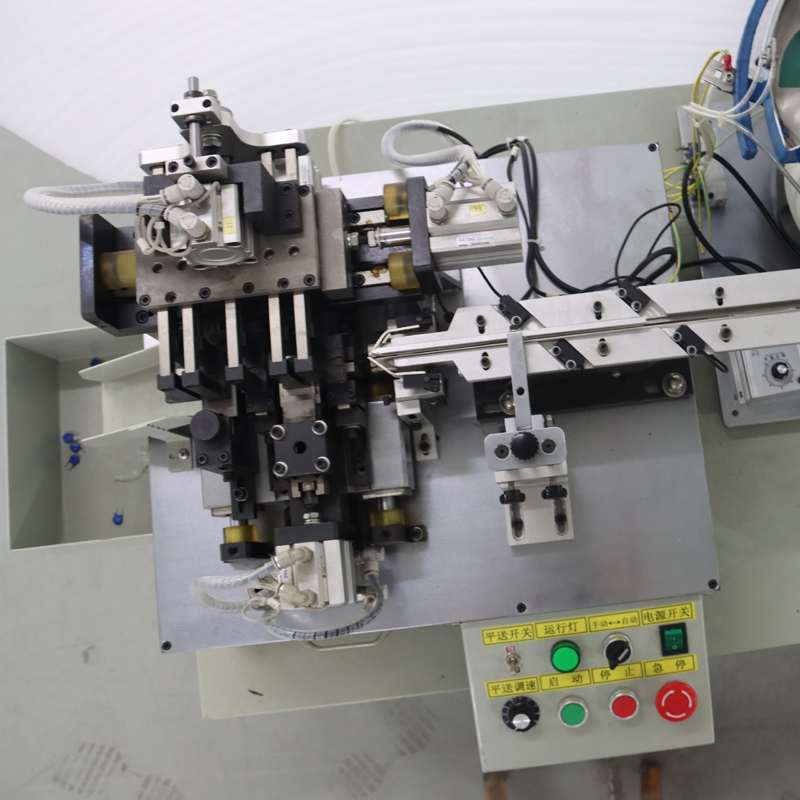

Brief introduction and classification of foot cutting machine

According to the speed foot cutter can be divided into high-speed and low-speed foot cutter. Capacitor foot cutter is to remove the excess foot pin of electronic components, the application of component foot cutter makes electronic enterprises to bring high efficiency and save manual operation tedious.

How to operate?

1.Pour the components into the shaker.

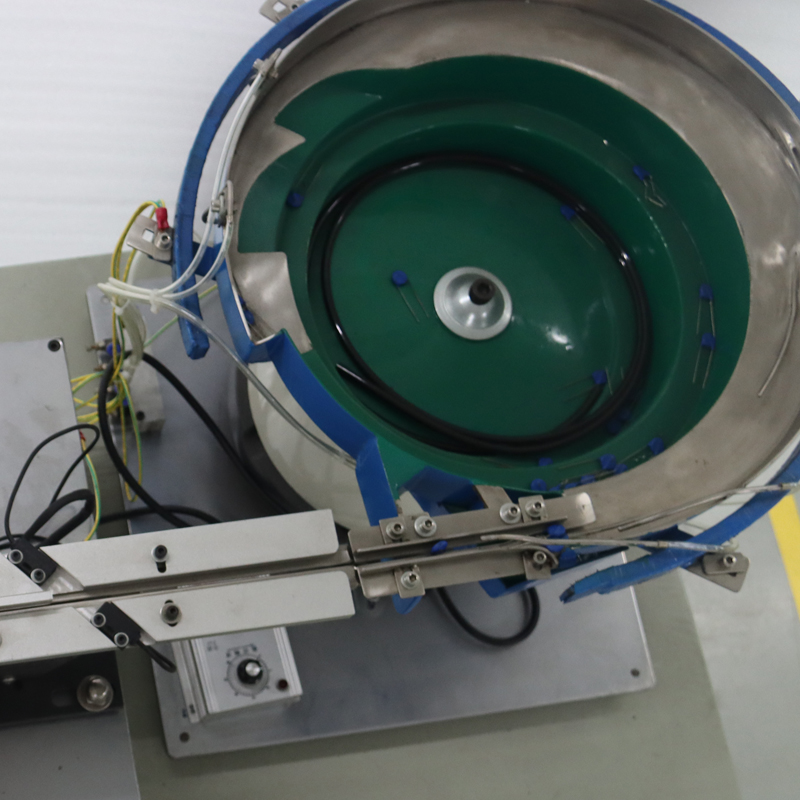

2.Turn on the power switch of the vibrating plate, adjust the vibration governor to control the feeding speed, so that the feeding speed can be appropriate.

3.To adjust the press track, adjust the press track according to the height of the component. Turn the knob on the pressure material guide bar, then the pressure material track can be moved up and down and adjusted to just press on top of the parts. However, the gap between the bottom surface of the press track and the body of the part is kept at 1.0mm-1.5mm.

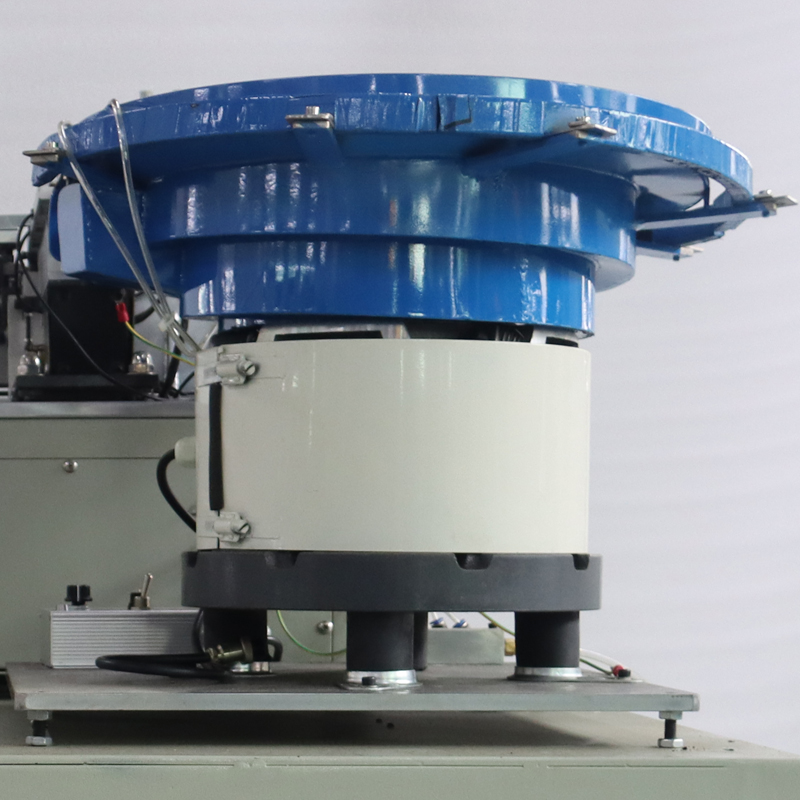

The role of the vibrating plate

Vibrating plate is a necessary feeding equipment for industrial production automation machinery, which is used for arranging, selecting, inspecting, counting and packing of goods according to the vibration to transfer the chaotic steel parts to the next process in an orderly and precise manner automatically.

Here to share with you what functions the vibration tray products generally have?

1.Easy to complete the operation and adjustment of bag making, fast speed, smooth operation and low noise: As the vibrating tray bag making system adopts stepper motor subdivision technology, it automatically tracks and positions the color code of the bag.

2.It adopts intelligent temperature control instrument with two-way control of horizontal and vertical sealing temperature, which makes the sealing firm, good sealing, flat and exquisite bag shape and high packing efficiency.

3.Adopt advanced intelligent photoelectric tracking system and automatic compensation function to ensure the automatic alignment of double-sided printing patterns of packaging bags and improve the utilization rate of packaging materials.

4.Tailor-made vibration tray and linear vibration arrangement device for screw samples, and precise counting control device ensure each bag is accurate.

Vibrating trays are widely used in various industries such as light industry machinery, automatic punching machines, office supplies, stationery, electronic appliances, clock and watch standard parts, pharmaceutical industry, hardware industry, plastic connectors, batteries, food packaging machinery, testing, etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.